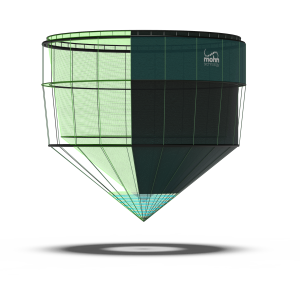

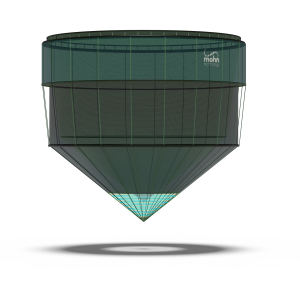

Mohn Technology has developed a semi-closed net pen called FlowFarm. The system is analysed by one of Norways leading Computational Fluid Dynamics (CFD) companies, CFD Marine.

The system is patented in Norway, Great Britain, Russia, Chile and Japan. It is also patent pending in Canada.

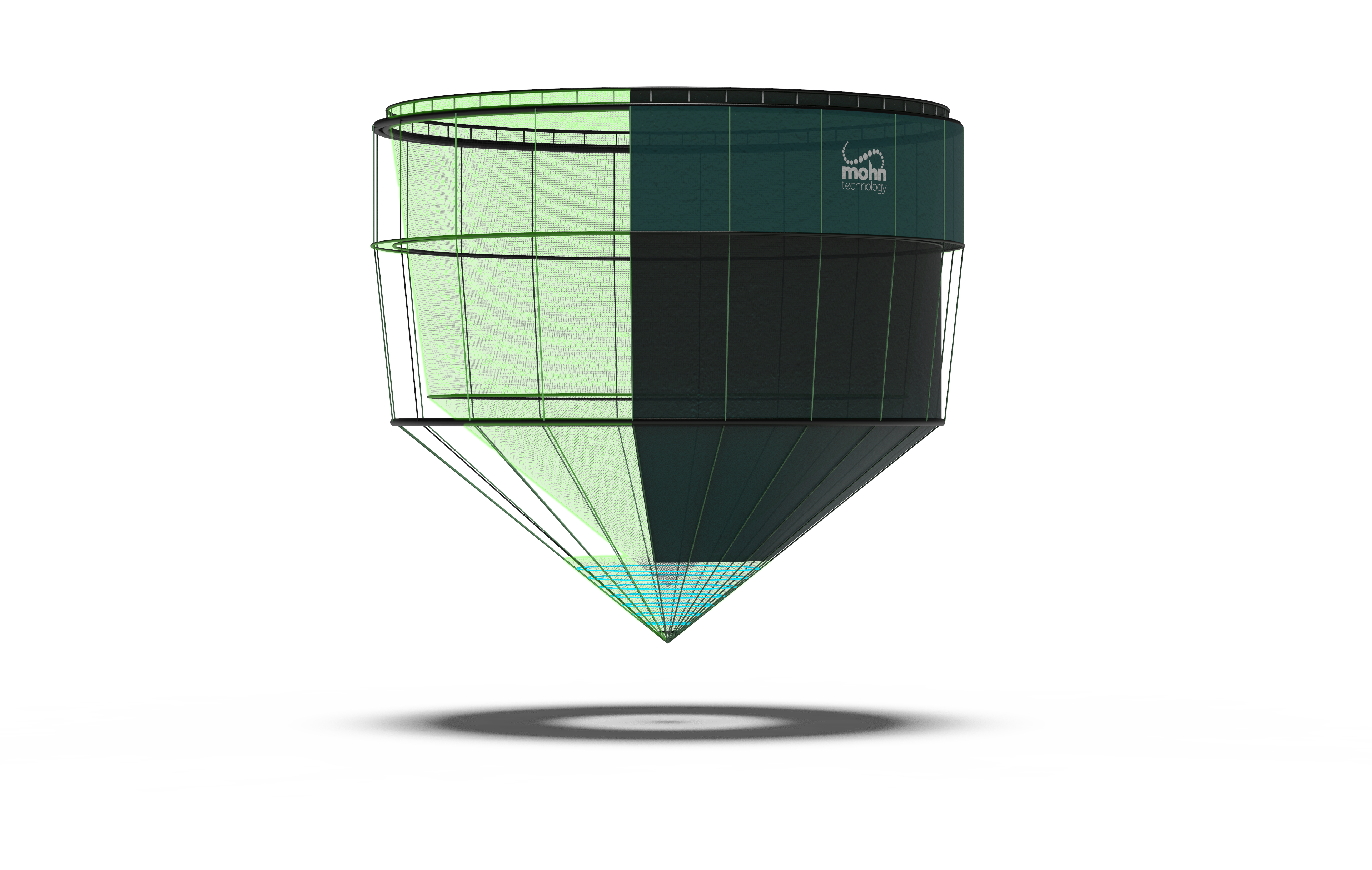

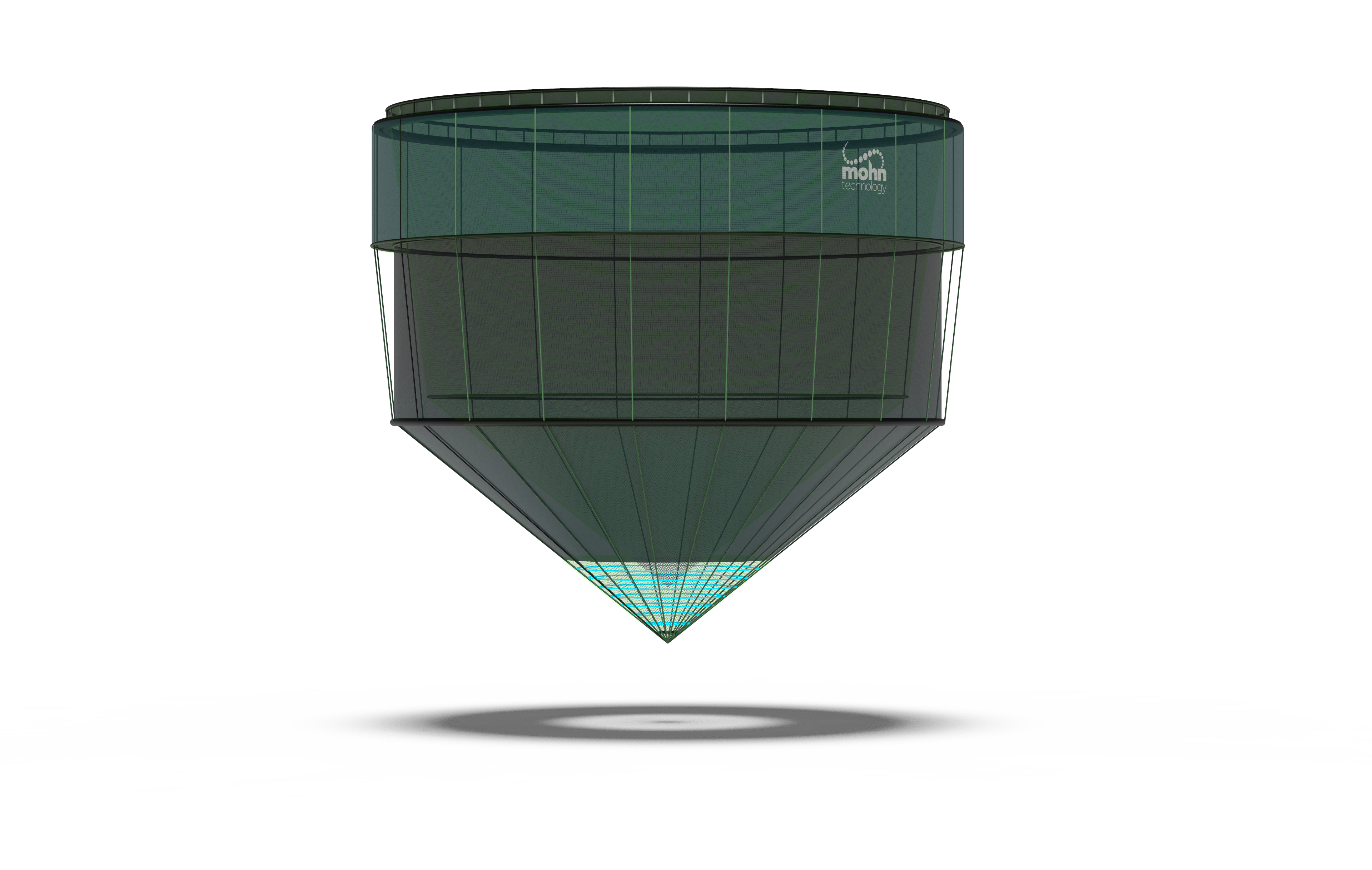

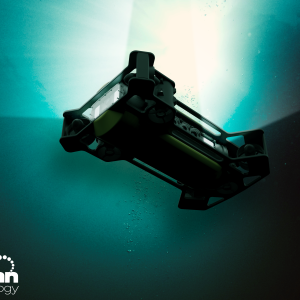

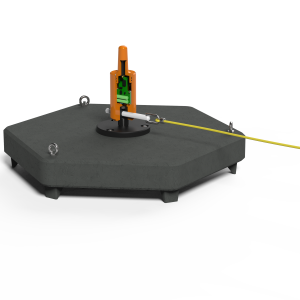

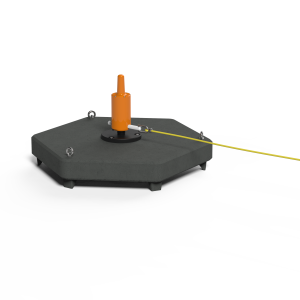

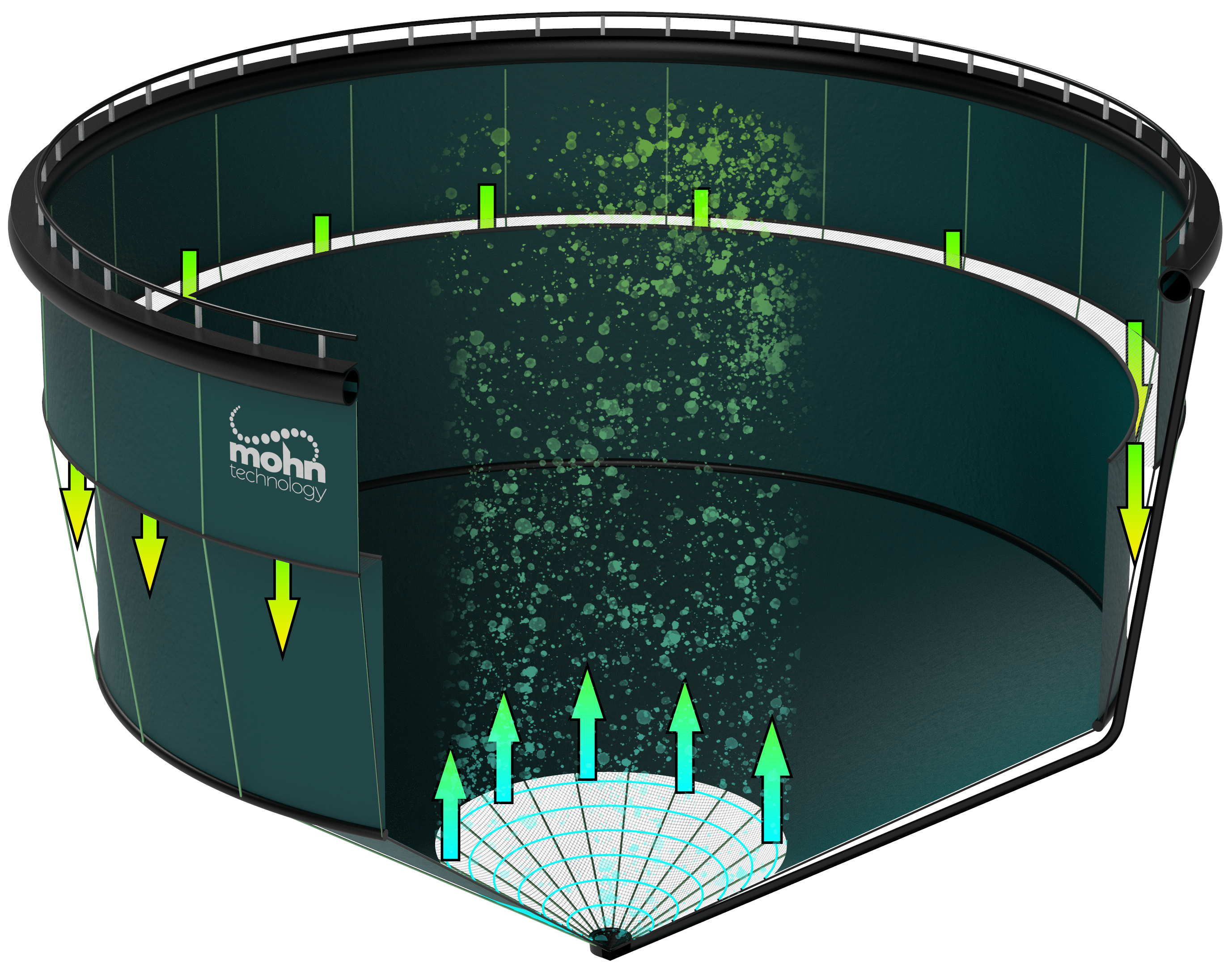

The FlowFarm netpen has a semi closed design, where the water intake is at 30m depth and the outlet around 8-10m. The flow is generated by the release of compressed air through a series of tubes in combination of an unique and patented design of the net pen. The water i pulled up towards the surface from the bottom inntake. The water is efficiently mixed with the existing water in the facility and evacuated through the outlet at the side. This flow principle leads to an energy efficient and even distribution of fresh water from below lice and algae levels. The FlowFarm is installed on the outside of the existin net pen, creating a dual barrier. This dramastically reduce the chance of escapes, and ensure the handling of the net pen is similar to standard designs.

CFD analyses of a 160m net pen gives the following results:

- Required compressor power: Ca. 20kW (16l/s compressed air)

- Resulting water flow: 32400 m^3/hour

- Exhaust water is not mixed with intake water, which is good for net pens in close proximity to each other.

- Oxygen can be mixed into the air system for increased oxygen levels if needed.

These results indicate an energy use of around 10% of current semi closed facilities. The flow rate is most likely similar (if not higher) on 120m net pens with the same power usage.

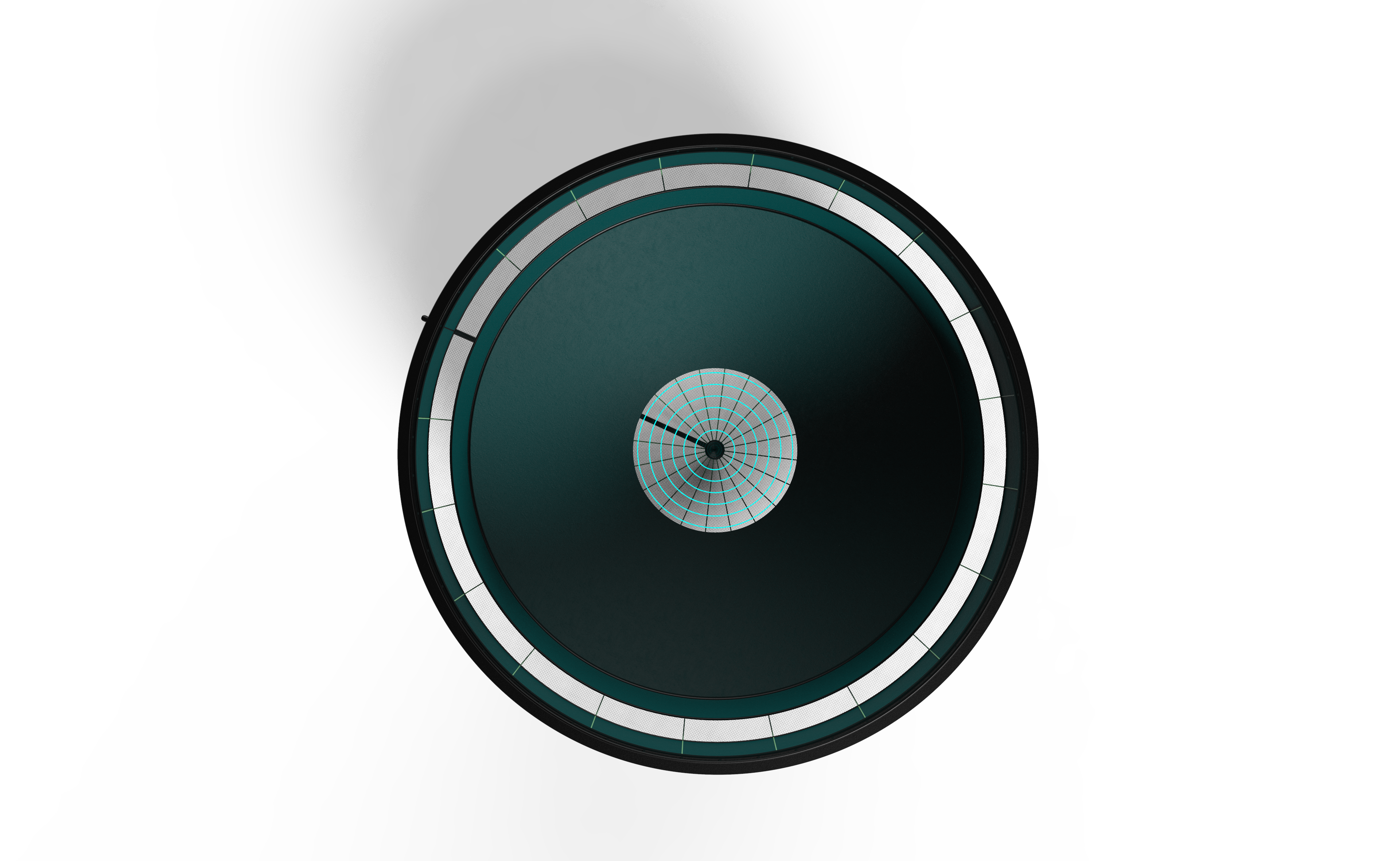

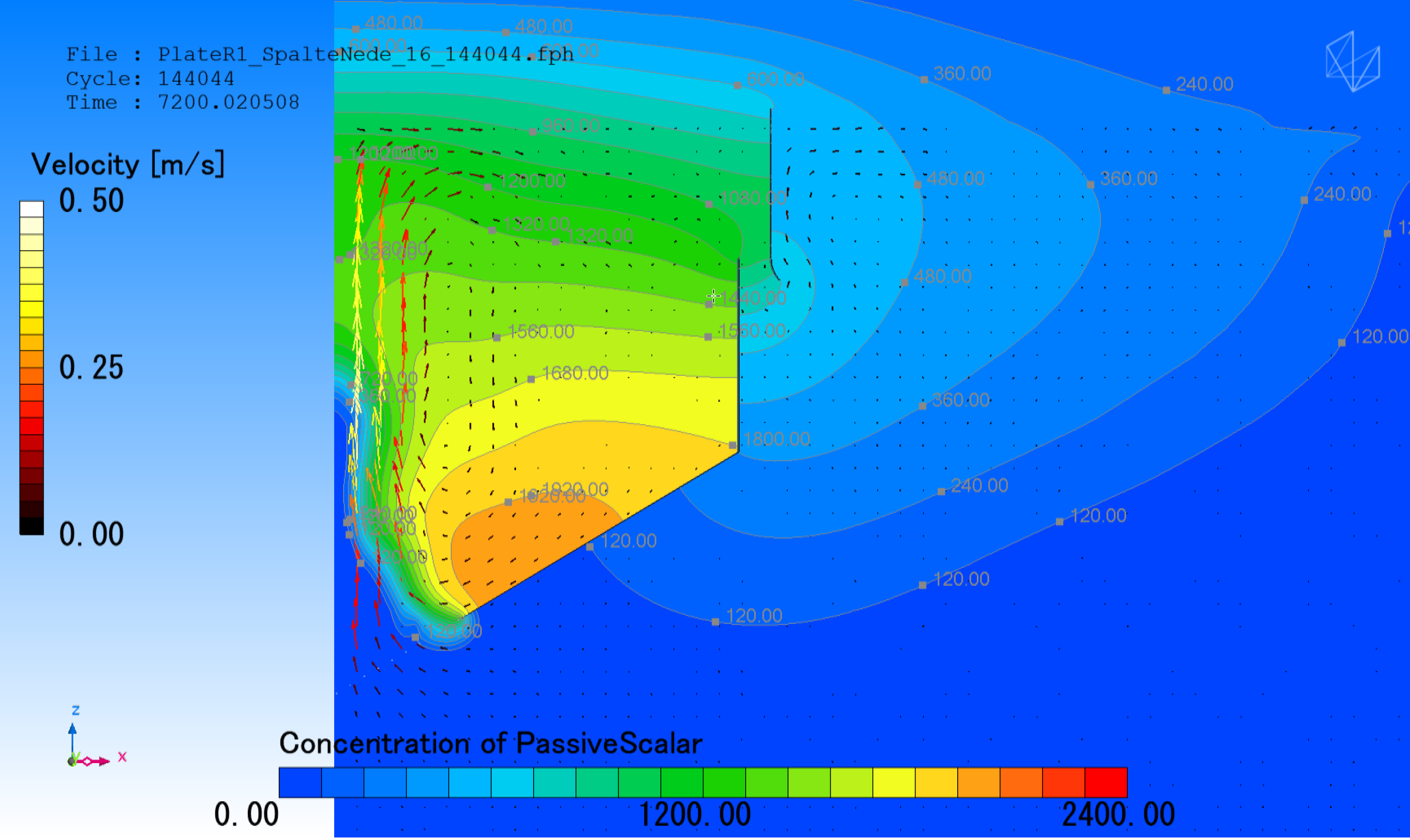

Plot below showing residence time and velocity vectors. Inlet water from the bottom is mixed with the large volume of the facility and ejected at the outer perimeter.

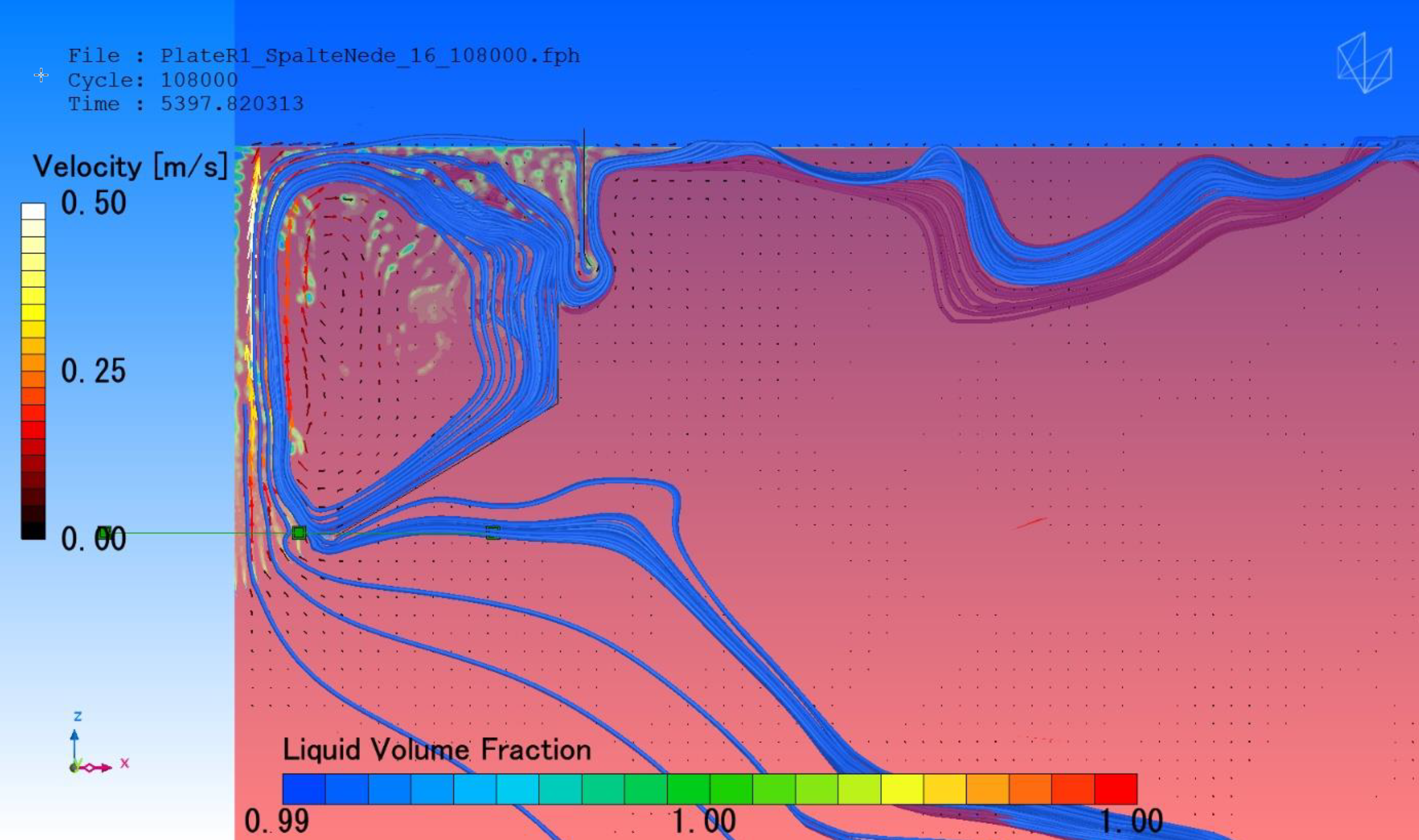

Streamlines showing how the water travels through the facility. The most interesting aspect here is that the inlet water does not mix with the outlet water outside of the facility. Due to the small air boubles included in the outlet water, it is slightly more buoyant than the surrounding water. It therefore keeps to the surface and makes sure that the inlet water does not mix with the outlet water, which has reduced oxygen levels.

Our solution addresses the challenges of fish farming in the following aspects:

Sea lice

The salmon louse is one of the biggest challenges for fish farmers today. The farmers have to follow strict guidelines given by the authorities, and if the levels of salmon lice is too high, they have to delouse the net pen. This both come at a substantial direct cost of the process, but also severe indirect costs of increased mortality and reduced growth. The salmon lice typically lives in the top of the water column, and shielding the farm salmon from this water will greatly reduce the infestation.

Killer algae

The so-called killer algae is a group of algae that is harmful to the farmed salmon. The algae is common along the coast, but at certain environmental conditions algal blooms can kill thousands of tonnes of salmon in a matter of days. These events are rare, but when they do occur the results are often catastrophic, like this event in 2019 when 7.5 million salmon died. There are probably many more incidents related to harmful algae, but only the larger cases are investigated, registered and covered by the media.

Temperature

We see a tendency to warmer water in the summer, and in northern parts of the globe the water temperature in the winter is far below optimal. When using a FlowFarm facility you will even out the temperature throughout the year, since the deeper water has a more stable temperature. This way you will cool the fish in the summer and heat the fish in the winter, which leads to much better growth conditions and living environment for the fish.

Contact us if you are interested in the product, either as a partner or pilot user.