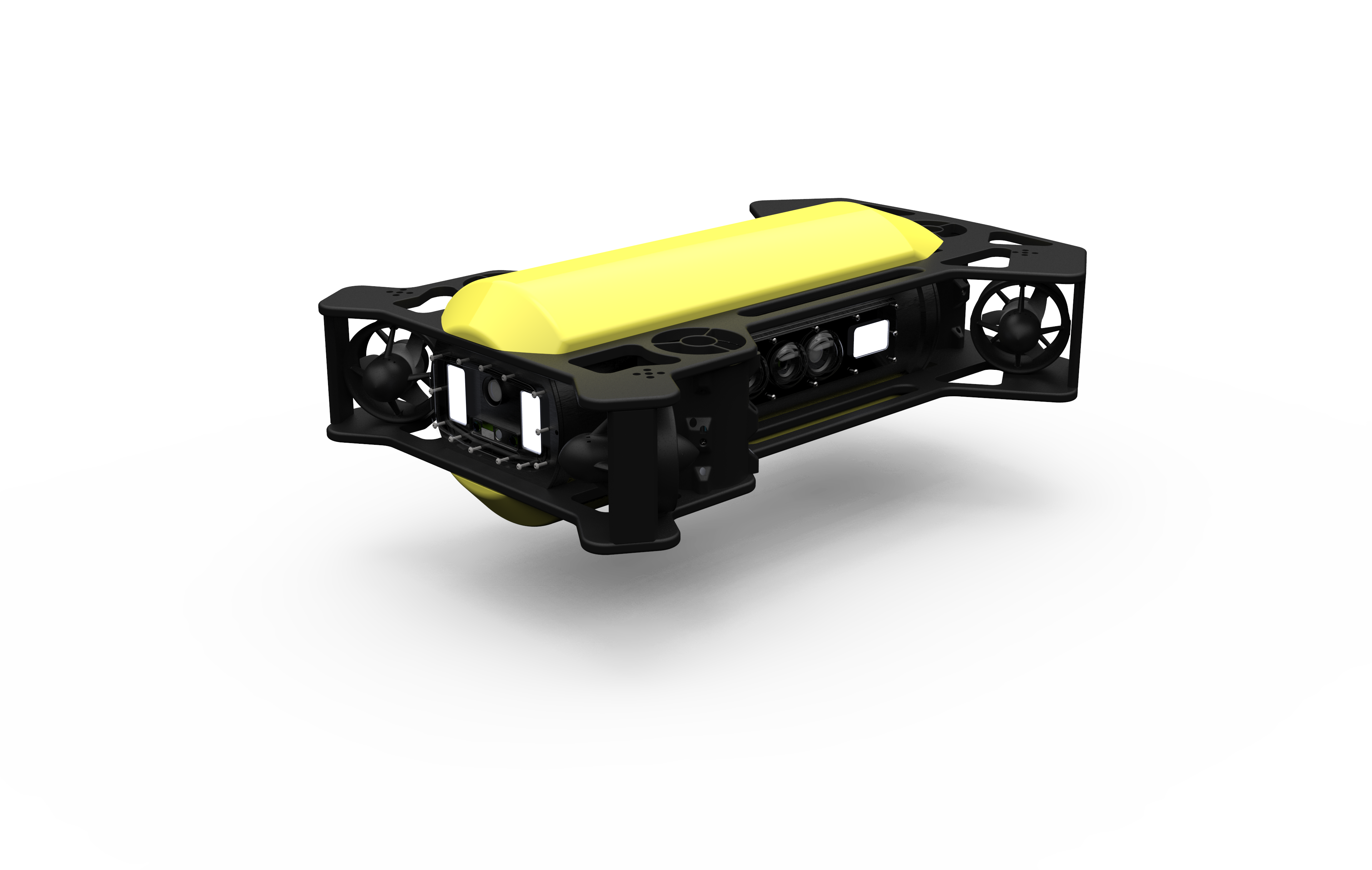

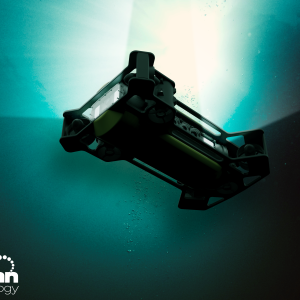

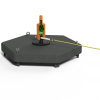

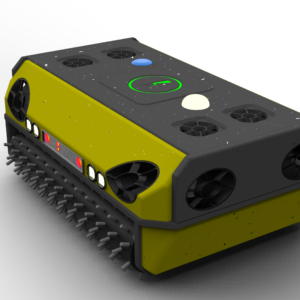

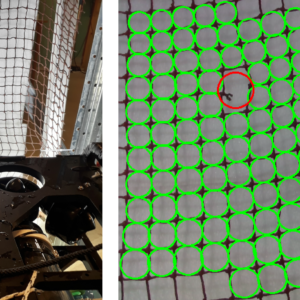

Mohn Technology AS is developing the Sentinel Inspection Drone (ID) with autonomous capabilities. The project is funded by FHF in a project requesting new tools to reduce risk farmed fish escaping. The first priority is therefore to serve the aquaculture industry, with focus on inspecting net and mooring integrity.

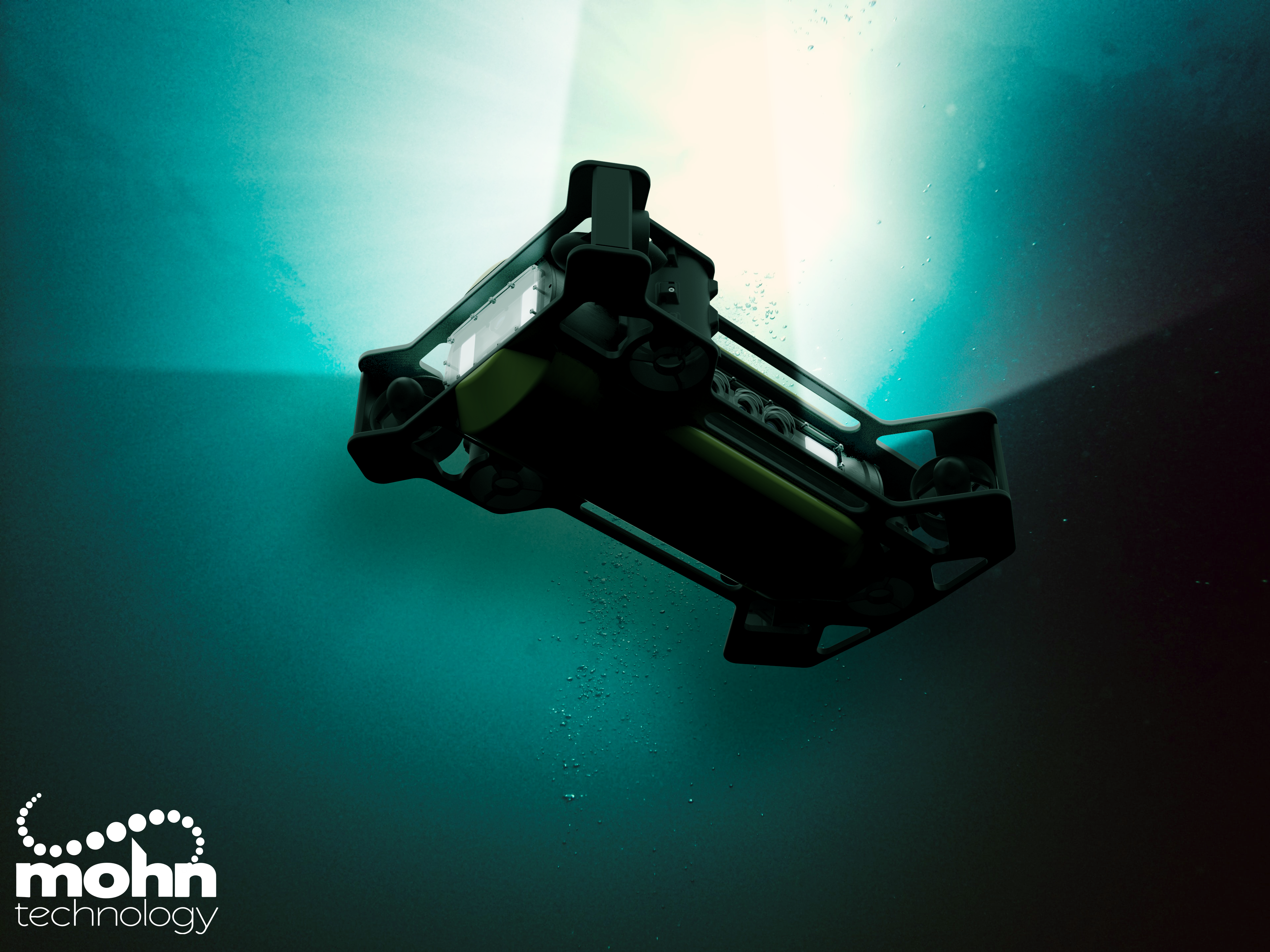

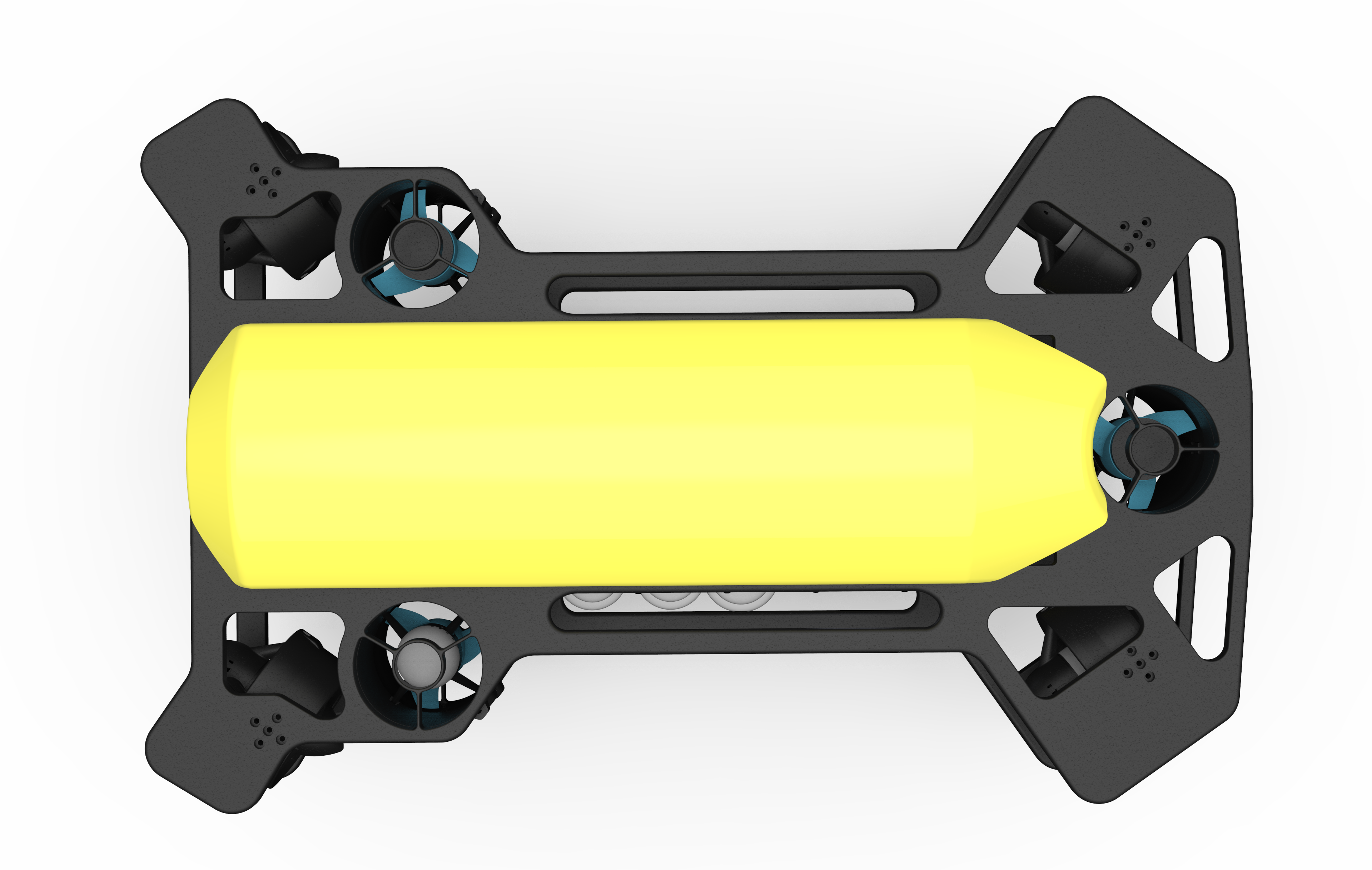

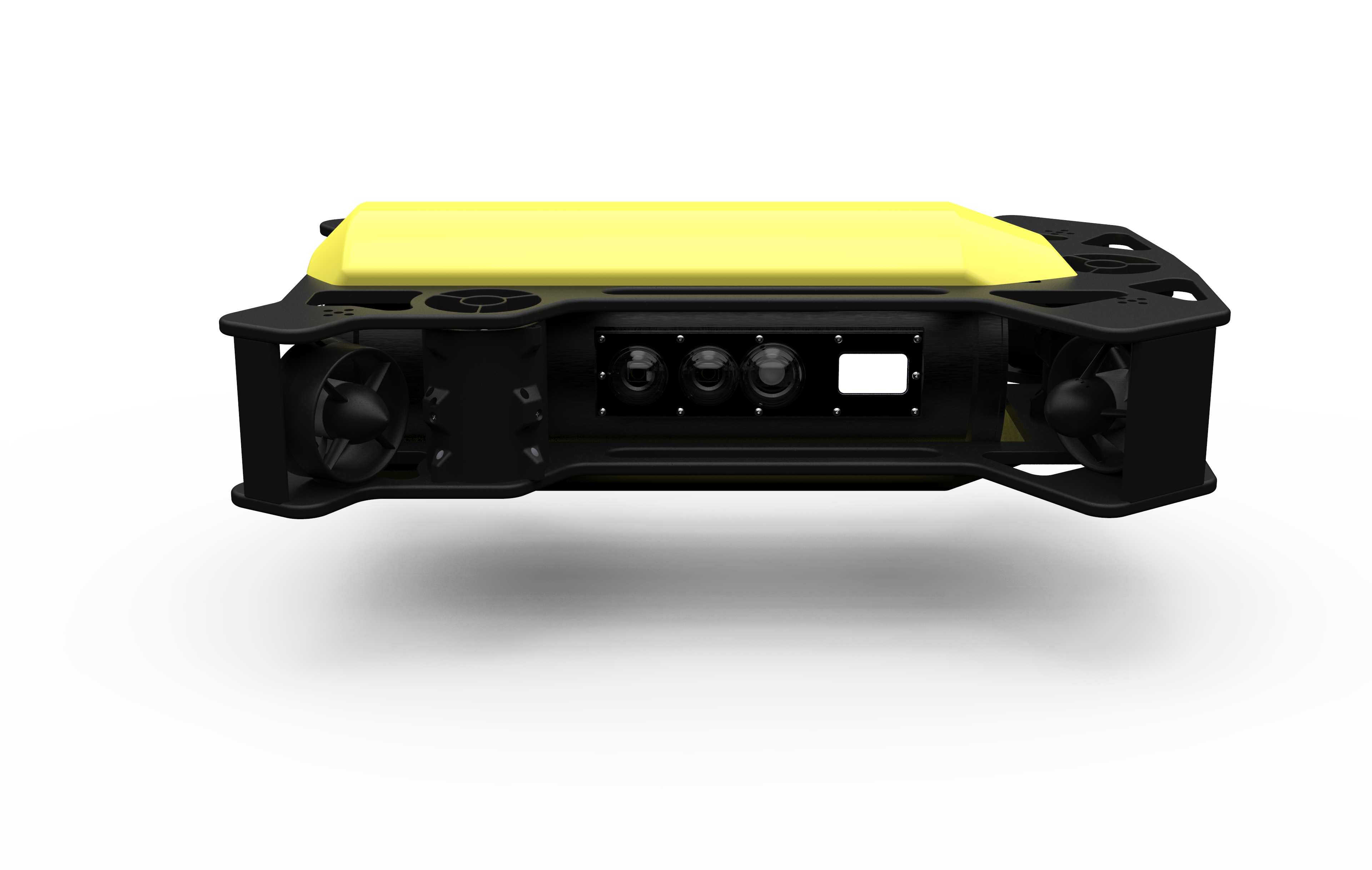

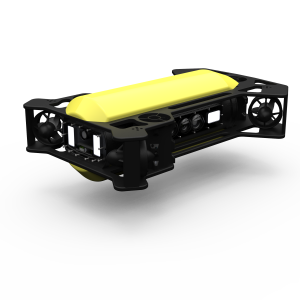

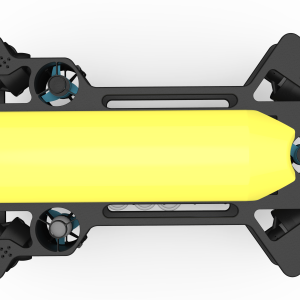

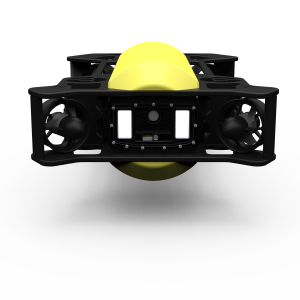

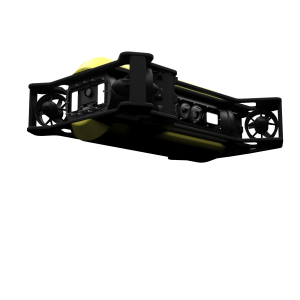

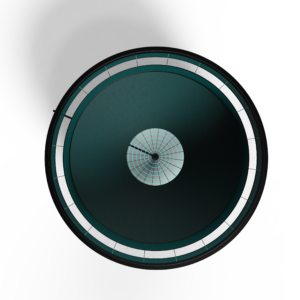

The Sentinel ID is battery powered, fully actuated by electric thrusters and has the ability to both navigate and inspect automatically. Our advantage is our self developed control system, that allows for a machine vision stabilised vehicle. Both the hardware and software for the motor controllers are developed by Mohn Technology, and this allows the Sentinel Inspection Drone to be both lightweight, quick and stable. This has been a compromise in the underwater vehicle industry for years, where heavy ROVs are used for inspection jobs due to the stability generated by their mass. The Sentinel Inspection Drone uses proprietary software to lock to the target and use the fast reaction control loop to compensate for any movement in the water generated by waves, turbulence or currents.

The system will have a weight of around 20 kgs, and include multiple sensors:

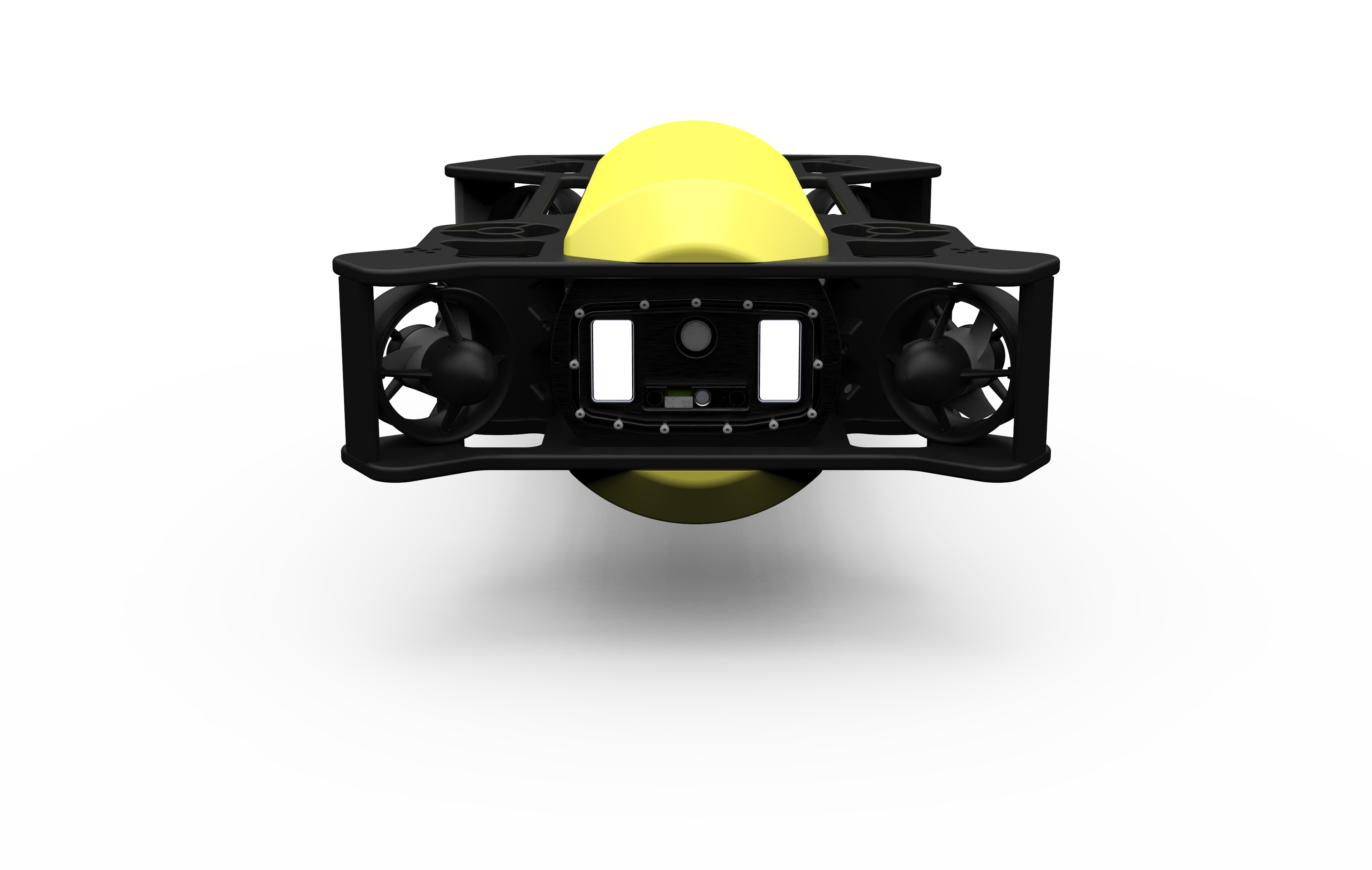

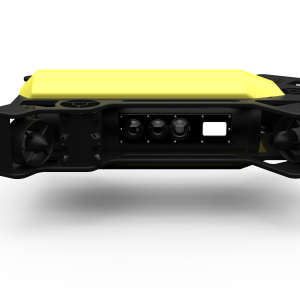

- 2 Stereo cameras (3D cameras)

- 2 Fisheye cameras

- Pressure sensor (depth)

- Temperature sensor

- Multi axis Gyro/accelerometer

- Compass

- Sonar

- uGPS / acoustic positioning system (optional)

- Other sensors can be added to the system if required by the user.

In addition to the sensors, the system includes a small but powerful onboard computer that saves operation data and analyze the images real time using both conventional and AI-based machine vision algorithms.

The system is developed and built in Bergen, Norway.

We are currently prototype testing and are aiming for pilot testing Q4 2023.